Sandiway Fong

June 2001

About three years ago I had an idea for a radical drop handlebar that would have all the positions of a normal drop handlebar plus allow one to get aero and low by dropping the center section. This would obviate the need for an aerobar.

At that time I was using a set of aerobars clamped to a set of normal handlebars, as shown here:

There are three main disadvantages of such a setup:

[Those of you who have a similar setup and don't believe this latter point, you have forgotten how a bike is meant to handle. Try it. Take off your aerobars, and do circles around in a parking lot before and after. Suddenly the bike responds way better.]

About a year later, I had a custom bike built. It used 650c instead of 700c wheels. Keeping the same minimal headtube length, you're instantly about 4cm lower. So I now have the additional drop I'd always thought I could use.

I had visions of having someone custom-bend me a drop handlebar to specification. However, fast forward to last year, I saw Performance having a sale on their copy of Cinelli's original Spinacci mini-aerobar. It was called the Strada and came with a cold-forged clamping mechanism that I could use. There are two holes 6cm apart. One end accepts tubing of 23.8mm diameter and the other 22.2mm; the extension being clamped here is 22.2cm OD.

Now the trick is simply to use an existing drop handlebar, cut it into three pieces and use the Strada clamps to join them. The basic concept is simple. Here is the latest implementation (sans bar wrap):

I used the newly introduced Easton EC90 carbon fiber handlebar, which is painted bright red and comes with dire warnings about clamping anything to them. Two reasons why I used the high-zoot Easton bar:

How do I get around Easton's warnings about clamping carbon fiber. The idea was to use aluminum inserts, epoxied into the ends. This neatly solved another problem, compatibility with the 22.2mm holes. See the center section below:

[Of course, another way to go might be to ream out the 22.2mm end to 23.8mm to match the other end, and to use a washer or something prevent the thin-wall carbon from being crushed by the clamp.]

Note, due to my requirement of a very short stem, I had to use a heavy mountain bike stem and tall spacer to get the position I needed. Weight of the above stem/center-piece section is 266g.

[Actually, I also goofed up a bit on the width of the center section. I forgot to take into account the extra width of the inserts, so the bar is actually a few cms too wide for me. This has been rectified in the current version.]

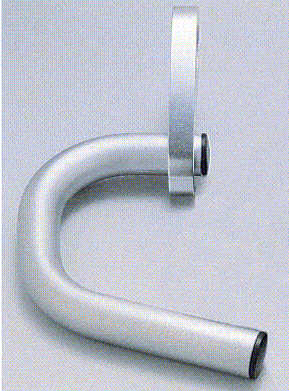

Anyway, I no longer use the above center section. Albert Bold (of Bold Precision) cut and welded a Specialized Ti stem directly to a 22.2mm (7/8") OD Ti tube (thickness .061") of length 24cm for me. This one piece design weighs 188g. You can see this more clearly here:

[It could have weighed less if we'd use 0.035" tubing. But better to be conservative here.]

Here is a slightly closer view:

The resulting combination has the standard drops and hoods positions in addition to the dropped center section. Some notes:

Put your hands in a bar-top configuration with the thumbs wrapped around the Strada clamps halfway down. It is surprising comfortable and you can yank hard when pushing against the pedals in the saddle on steep grades. It's now my favourite hand position for climbing.

That's all Folks!!!